The little heroes of mountain bike pedals - everything about pins and their influence on grip and functionality

When it comes to mountain bike pedals, it's often the little details that make the difference. One of these important details are the pins – small pins that establish contact between the shoe and the flat pedal and provide the crucial grip. But the pins are by no means just inconspicuous accessories; they have a significant impact on the overall function of the pedals. In this article, we will take a closer look at how the quality, shape, length, arrangement and quantity of pins affect the driving experience.

Material and quality:

The quality of the pin material plays a big role. Tempered steel in grades 10.9 or 12.9 are resistant to wear and provide long-lasting grip. Softer materials can wear or bend, resulting in loss of traction.

Shape and length of the pins:

The shape of the pins influences the contact with the shoe and is responsible for the resistance. A good compromise between the aggressiveness of the pins (the thinner the more snappy) and durability (the thicker the stronger) is a diameter between 3.0 and 3.6mm. The grip of the pins can be increased by adding a recess at the tip.

The length of the pins is crucial for how deeply the shoe can penetrate the pin and how much pressure is built up on the sole. The correct length ensures sufficient grip, although the tread depth of the shoes should be taken into account. If the grip is too low, the platform pedal can be optimized with longer pins.

Arrangement of the pins:

The position of the pins on the pedal body influences the distribution of grip. A well-thought-out arrangement ensures that the pressure is evenly distributed across the foot and that grip is guaranteed even when the shoe is positioned in different ways. The example of the LINK pedal with 3 different ones Pin setup variants shows how the arrangement of the pins influences the function.

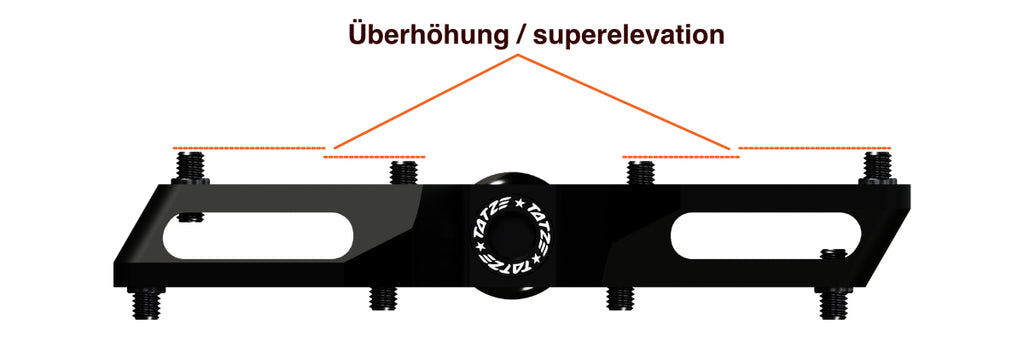

Pins that are installed at different heights (concave arrangement) are adapted to the shape of the shoe and increase the grip level.

Number of pins per pedal side:

The number of pins per side of the pedal influences both the grip level and the weight of the pedal. More pins mean more possible contact points and therefore more grip. Ultimately, the number of pins required also depends on the condition of the shoe sole, because a jagged hiking or mountain shoe sole (e.g. for bike mountaineering or often used by eBikers) means that some pins cannot make contact with the shoe or can make insufficient contact. In this case, optimal is one Pedal with as many pins as possible to use. On the other hand, 10-12 pins are usually sufficient for flat soles of flat pedal shoes, as each pin can establish contact with the shoe.

A little-noticed fact is that the shape and number of pins have a significant impact on the weight of the pedal. One pin weighs 0.5 - 1.0 grams, which means up to 24g more weight for a pedal with 8 pins per pedal side compared to 14 pins.

Thread dimensions of the pins: M3 + M4

In practice, two common thread sizes for pins have been established: M4 and M3. Pedals with aluminum pedal bodies mostly use M4 threads, while plastic pedals use pins with M3 threads, which are secured with embedded nuts in the pedal body.

Conclusion: Why pins on mountain bike pedals?

In summary, the pins on mountain bike pedals play a crucial role in grip and function. The right selection of material, shape, length, arrangement and quantity of pins can significantly improve the driving experience.

By developing your own pins, these can be optimally tailored to the pedal. But if you already have a pedal and want to tune it, you can do so with the matching pins adapt to his needs.

Replacement pins for pedals from Shimano, Crankbrothers, Hope, One Up and Race Face:

Here are some aluminum flat pedals where TATZE M4 pins can be used:- Crankbrothers Stamp aluminum or magnesium

- Shimano Saint

- One Up Aluminum

- Hope F20/F22

- Race Face Atlas

- One Up Comp

- Crankbrothers Stamp 1 (Generation 1)

- Race Face Chester

- Shimano PD-GR400

Here is a selection of pins for flat pedals

A: 6.5mm long M4 pin with hex drive

B: 5.0mm / 6.3mm long and reversible M4 PIN with Allen drive

C: 4.5mm long M4 pin with hex drive

D: 3.75mm / 4.75mm long M3 pin with Allen drive

E: M3 pin with nut, screw bolt 10mm long

Q: M3 pin with nut, screw bolt 8mm long